The development of transparent aluminum armor represents a groundbreaking fusion of advanced materials science and practical applications across military and civilian sectors. This remarkable innovation, rooted in the manipulation of alumina nanoparticles, has evolved from laboratory curiosity to real-world solutions that redefine conventional notions of protective materials.

From Ballistic Protection to Everyday Applications

Initially conceived as a next-generation armor system for military vehicles and aircraft canopies, transparent aluminum composites demonstrate exceptional resistance to high-velocity impacts while maintaining optical clarity. The material's unique nanostructure dissipates kinetic energy through controlled deformation mechanisms at the atomic level, offering protection comparable to traditional opaque armor at a fraction of the weight. What began as defense research has now permeated civilian markets, with architects incorporating the material into blast-resistant windows for high-security buildings and automotive engineers testing its viability for lightweight, shatterproof windshields.

The transition from military to civilian use followed a familiar pattern of technology transfer, though accelerated by the material's inherent advantages. Unlike many defense technologies that require extensive modification for civilian adoption, transparent aluminum armor presented immediate benefits for commercial applications. Its combination of durability, light weight, and optical transparency solved multiple engineering challenges simultaneously, creating demand across diverse industries.

The Science Behind the Transparency

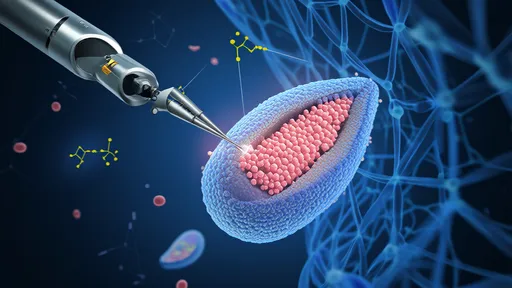

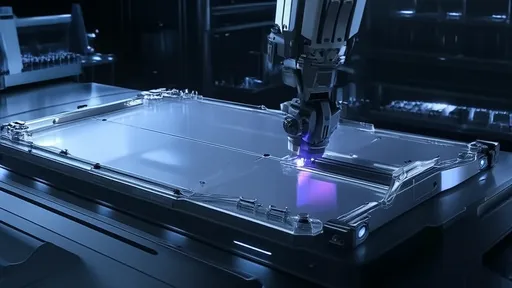

At the heart of this innovation lies a sophisticated understanding of alumina nanocrystals and their optical properties. Researchers achieved transparency not by creating perfectly clear aluminum in the traditional sense, but by engineering ceramic composites with crystalline structures that permit light transmission while maintaining metallic strength. The precise alignment of nanoparticles within the matrix prevents light scattering at grain boundaries, allowing visible wavelengths to pass through with minimal distortion.

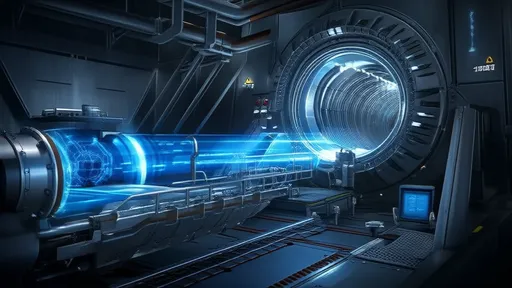

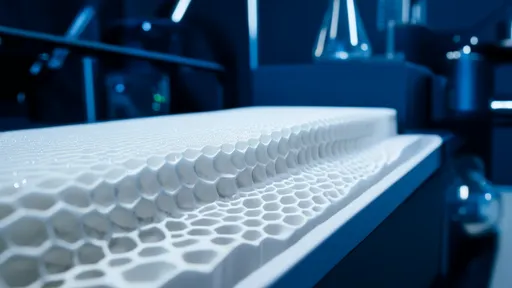

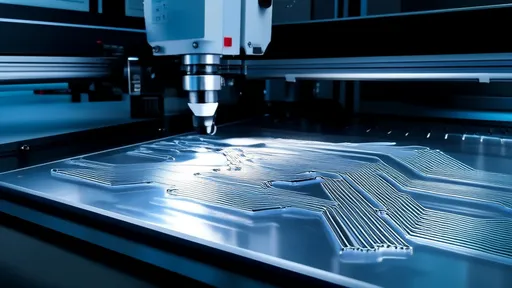

Manufacturing breakthroughs enabled the scaling of this technology from laboratory samples to practical sheet materials. Advanced sintering techniques combined with pressure-assisted crystallization processes allow for the creation of large-area panels with consistent optical and mechanical properties. These production methods continue to evolve, gradually reducing costs and expanding potential applications.

Current Military Deployments

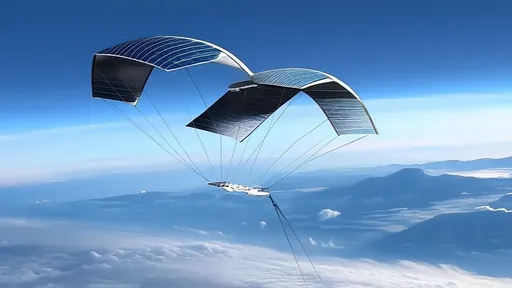

Several defense forces have begun limited deployment of transparent aluminum armor systems, primarily for specialized vehicles and aircraft where visibility and protection are equally critical. Early field reports indicate the material performs exceptionally well against small arms fire and shell fragments, with the added benefit of reducing overall vehicle weight. This weight reduction translates to improved fuel efficiency and payload capacity - factors that significantly impact operational effectiveness in combat scenarios.

Naval applications are particularly promising, as the material's resistance to corrosion in marine environments combines with its ballistic properties to offer ideal solutions for ship windows and protective barriers. Aviation uses extend beyond military aircraft, with commercial aerospace manufacturers evaluating the technology for cockpit windows that could better withstand bird strikes and debris impacts.

Civilian Market Penetration

The civilian adoption of transparent aluminum technologies has progressed faster than many analysts predicted. High-end automotive manufacturers now offer it as an option for luxury vehicles, while critical infrastructure projects incorporate the material for hurricane-resistant windows in coastal areas. Perhaps most surprisingly, consumer electronics companies have begun experimenting with transparent aluminum as a premium alternative to traditional glass for smartphone screens and wearable devices.

Medical applications are emerging as well, with surgical tools and protective barriers utilizing the material's combination of sterility and durability. The healthcare industry values its ability to withstand repeated sterilization cycles without degradation, a limitation of many transparent materials currently in use. Research hospitals are testing its viability for radiation shielding in diagnostic imaging suites, where lead glass has traditionally been the only option.

Economic and Manufacturing Considerations

As production volumes increase, economies of scale are beginning to make transparent aluminum more accessible to mainstream markets. Early adopters paid premium prices for the material, but current projections suggest costs could decrease by 40-60% within the next five years as manufacturing processes mature. Several startups have entered the space with novel production approaches, challenging traditional defense contractors who initially controlled the technology.

The supply chain for high-purity alumina nanoparticles - the raw material essential for creating transparent aluminum - has expanded dramatically to meet growing demand. Mining operations have adjusted their refining processes to produce the specific particle sizes and crystalline structures required, while recycling initiatives aim to recover alumina from industrial waste streams for repurposing into high-value transparent composites.

Future Directions and Challenges

Research continues to push the boundaries of what transparent aluminum materials can achieve. Teams are working on versions with adjustable opacity, allowing the material to switch between transparent and shaded states electronically. Other efforts focus on enhancing the material's thermal insulation properties or developing self-healing variants that can repair minor damage automatically.

Despite these advancements, challenges remain. The material currently lacks the elasticity of traditional glass, making it less ideal for applications requiring significant flexibility. Researchers are also working to improve the material's resistance to certain types of directed energy weapons, an increasingly important consideration for military applications. For civilian uses, long-term weathering performance and maintenance requirements continue to be evaluated through extended real-world testing.

The story of transparent aluminum armor exemplifies how cutting-edge materials can transition from specialized military applications to widespread civilian use. As the technology matures, it promises to redefine our expectations of transparent structural materials across countless industries, demonstrating once again how defense-driven innovation can catalyze broader technological progress.

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025

By /Jul 18, 2025